We provide the best value to our customers by continuously refining our

Production of Steel and Galvanized Angle Bars and U-Channels

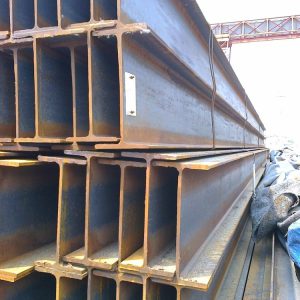

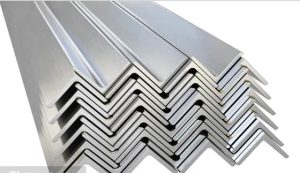

Steel & Galvanized Angle Bars and U-Channels

Precision-rolled equal and unequal angle bars and U-channels for structural framing, bracing, and fabrication.

Product Overview

Enginmac Technologies Limited manufactures high-quality mild steel angle bars (L-sections) and U-channels using advanced CNC roll-forming and laser-guided cutting technology at our Spintex-Accra facility. All products are available in black steel or hot-dip galvanized finish for superior strength and long-term corrosion protection.

Our galvanized angle bars and U-channels carry a minimum zinc coating of 550 g/m², making them ideal for outdoor structures, roofing supports, and coastal construction projects.

Key Features

- 100% manufactured in Ghana with full traceability

- Equal and unequal angles available

- Hot-dip galvanized option (550+ g/m² zinc coating)

- Precision-cut lengths from 3m to 12m

- Laser-measured tolerances for perfect fit

- Custom punching and drilling on request

- Same-day dispatch for standard sizes

Technical Specifications

| Parameter | Angle Bars (L-Section) | U-Channels |

|---|---|---|

| Material | Q235B / S275 / S355 | Q235B / S275 |

| Type | Equal & Unequal | Plain & Slotted |

| Common Sizes (Angle) | 25×25 to 150×150 mm | — |

| Common Sizes (U-Channel) | — | 50×25 to 200×75 mm |

| Thickness | 3 – 12 mm | 3 – 6 mm |

| Standard Length | 6 meters (custom cutting available) | 6 meters |

| Zinc Coating (GI) | Min. 550 g/m² | Min. 550 g/m² |

| Standards | BS EN 10025, ASTM A36 | BS EN 10025 |

Most popular stock sizes: 25×25×3, 40×40×4, 50×50×5, 75×50×6 mm (angles) • 100×50×5, 150×75×6 mm (U-channels)

Production Process

- High-grade HR coil inspection and slitting

- CNC roll-forming with automatic welding

- Precision straightening and laser length measurement

- Hot-dip galvanizing at 450–460°C (for GI products)

- Cooling and chromate passivation

- Custom hole punching and cutting (optional)

- Final dimensional and visual inspection

- Bundling and protective packaging

Product Gallery

Common Applications

Roof trusses • Steel towers • Transmission line supports • Warehouse racking • Trailer chassis • Fencing frames • Bracing & reinforcement • Gate fabrication • General structural steelwork

Get in Touch

Call / WhatsApp:

055 729 4708 •

030 395 9974

Email:

info@enginmactechnologies.com

Enginmac Technologies Limited – Engineering Strength. Securing Tomorrow.